Since we are long term supplier of many huge international companies like walmart, amazon and Herman Miller. We maintain exceptionally high standards for product quality, utilizing advanced testing equipment and precision sorting systems to ensure superior pass rates. Our facility houses high strength fasteners testing capabilities including salt spray chambers (exceeding 96+ hours), coating cleaners, roller sorters, and precision optical inspection systems. We continuously expand our capacity to deliver stainless steel fasteners and corrosion resistant solutions for critical applications like automotive fasteners and industrial machinery fasteners.

This is the salt spray testing machine, we put the fastener(or other metal parts) on the V shelf in the center, close the cap. than the machine will atomizes 5% NaCl solution into corrosive mist at 35°C. Chloride ions accelerate electrochemical oxidation, evaluating corrosion resistance by recording time to red rust. Critical for fastener quality validation and coating performance testing. For most of our exporting fasteners for international companies, our salt spray test will be more than 96 hours.

Roller sorters rapidly grade fasteners via rotating shafts with calibrated gaps. They perform high-volume dimensional sorting, expelling undersized/bent parts while retaining compliant items. Key applications: detecting thread pitch deviations, diameter sorting, and length tolerance verification for bolts/nuts. Achieves 99.5% sorting accuracy at 2,000 PPM.

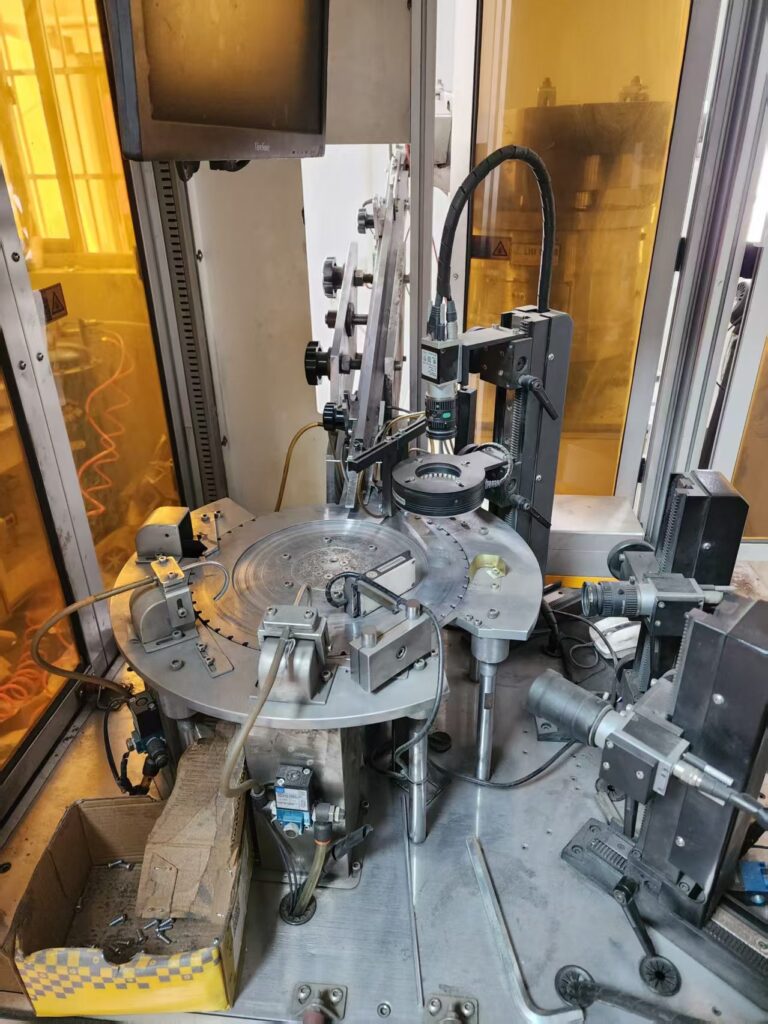

This is optical sorting machine, will sorting the flaws of the fasteners and screen out non-conforming items. Vision-based inspection systems utilize multi-angle cameras (5-20MP) with deep learning algorithms for micron-level defect identification. Scans for surface cracks, micro-burrs, coating uniformity, and geometric anomalies. Executes real-time defect classification and automated rejection. Critical for medical fastener validation and AS9100-compliant aerospace components.

2025/6/25

boltech

hugh

一条评论