Why do correctly torqued bolts still fail? It’s a question that plagues engineers and technicians across every industry, from automotive assembly to structural steel erection. The answer often lies in a fundamental misunderstanding between two critical concepts: Torque and Preload.

While we use a torque wrench to tighten a fastener, the torque value itself is not the goal. It is merely the means to an end. The true objective, the force that holds a joint together and ensures its safety and reliability, is Preload.

This in-depth guide will explore the critical relationship between torque and tension, explain why preload is what truly matters, and outline advanced methods for achieving accurate clamp load in your most critical applications.

What is Torque? The Means to an End

In simple terms, torque is the measure of a rotational or twisting force. When you use a wrench to tighten a nut, you are applying torque. It is calculated by a simple formula:

Torque = Force x Distance (the length of the wrench handle)

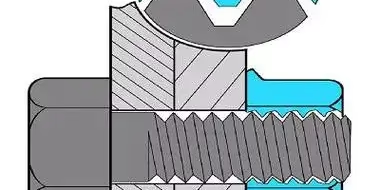

Applying torque to a nut causes the bolt to stretch like a spring. This stretching is what creates the clamping force. However, the relationship between the torque you apply and the resulting tension is far from perfect.

What is Preload (Clamp Load)? The Ultimate Goal

Preload, often called clamp load or bolt tension, is the axial stretching force created in a bolt when it is tightened. This tension is the critical force that clamps two or more components together.

Achieving the correct preload is paramount for the integrity of a bolted joint for several key reasons:

- It Prevents Loosening: Sufficient preload creates high friction between the thread surfaces and the nut/bolt head face, which is the primary defense against vibrational loosening.

- It Increases Fatigue Life: A properly preloaded bolt experiences much smaller changes in stress when subjected to external dynamic loads, dramatically increasing its resistance to fatigue failure.

- It Ensures Joint Strength: For friction-grip joints, it’s the clamp load that prevents parts from slipping relative to each other.

In short: You don’t want a specific torque value; you want a specific preload value.

The Problem: Why Torque Is an Inaccurate Measure of Preload

Here is the most critical concept to understand: the vast majority of the torque energy you apply with a wrench does not contribute to useful preload.

https://www.surebolt.com/Friction-Example-1-BS.htm

On average, the energy from your applied torque is distributed as follows:

- ~50% is lost to friction between the bolt head or nut face and the surface it’s clamping.

- ~40% is lost to friction within the threads themselves.

- Only ~10% is converted into useful preload (bolt stretch).

This means that any factor affecting friction will have a massive impact on the final preload, even if the applied torque is identical every time.

Factors That Dramatically Affect the Torque-Tension Relationship

The relationship between torque and tension is defined by a variable called the Nut Factor or K-Factor. The problem is, this “factor” is not a constant. It is highly sensitive to a range of variables:

- Friction & Surface Finish: A smooth, plated surface will have a different friction value than a rough, un-plated surface. The type of coating (e.g., Zinc, Cadmium, Dacromet, Geomet) has a significant effect.

- Lubrication: This is the single biggest variable. A lubricated bolt can achieve twice the preload as a dry bolt using the exact same torque. The type of lubricant (oil, grease, anti-seize paste) also matters immensely. Using an unspecified lubricant is one of the most common causes of bolt failure (over-tensioning) or joint failure (insufficient tension).

- Material and Geometry: The bolt material, diameter, and thread pitch (coarse or fine) all influence the relationship.

- Operator and Tooling: The speed of tightening, the accuracy of the torque wrench, and whether a socket extension is used can all introduce variations.

- Debris or Damage: Rust, dirt, or damaged threads can dramatically increase friction, leading to very low preload despite achieving the target torque.

The Formula: How to Calculate Preload from Torque (Theoretically)

The simplified formula used to relate torque and preload is:

T = K * D * F

Where:

T= Target TorqueK= The Nut Factor / K-Factor / Torque CoefficientD= The Nominal Bolt DiameterF= The Target Preload (Bolt Tension)

While this formula is useful, its accuracy is entirely dependent on knowing the correct K-Factor. Generic K-Factor values (e.g., 0.20 for dry, un-plated steel) are only a rough starting point. For critical applications, the K-Factor must be determined empirically under the actual assembly conditions.

Beyond Torque Control: Advanced Methods for Accurate Preload

Because of the inaccuracies of the torque-only method, engineers have developed more reliable techniques for applications where precise clamp load is non-negotiable.

Torque-Angle Tightening Method

This is a two-step process that provides much higher accuracy.

- Snug Torque: A low initial torque is applied to bring all joint surfaces into full contact (the “snug” point).

- Angle of Turn: From the snug point, the nut is turned through a specific, calculated angle. Because the angle of turn is directly proportional to bolt stretch (after snugging), this method largely bypasses the variables of friction.

Yield Control Tightening (Torque-to-Yield)

This method involves tightening a fastener until it begins to permanently (plastically) deform. It achieves the maximum possible preload for a given bolt but requires special “Torque-to-Yield” (TTY) bolts that must never be reused. It’s common in automotive engine assembly.

Hydraulic Tensioning

For large-diameter, critical bolts (e.g., in wind turbines, pressure vessels), hydraulic tensioners are used. These tools grip the bolt and stretch it directly with hydraulic pressure. The nut is then turned down to lock in the tension. This method completely eliminates friction from the equation, providing extremely accurate and repeatable preload.

Direct Tension Indicating (DTI) Washers

These are special washers with protrusions that compress as the bolt is tensioned. When the protrusions flatten to a specific gap, it provides a visual and physical confirmation that the required minimum preload has been achieved.

Best Practices for Reliable Bolted Joints

- Prioritize Preload, Not Torque: Always base your design on the required clamp load. Use torque only as a means to achieve it.

- Control Friction: Follow specifications for lubrication precisely. If no lubrication is specified, assemble parts clean and dry. Never add an un-specified lubricant.

- Use Calibrated Tooling: Ensure your torque wrenches are regularly calibrated and used correctly.

- Follow Tightening Patterns: For multi-bolt joints, always tighten in a star or cross pattern to ensure even clamping pressure.

- Never Reuse TTY Bolts: If a component uses torque-to-yield bolts, they must be replaced every time they are loosened.

- Consult the Experts: For critical applications, don’t guess. Work with fastening technology experts to define the correct procedure and tooling.

Conclusion: Master Preload, Ensure Reliability

Shifting your focus from simply hitting a torque number to truly controlling preload is the most important step you can take toward ensuring the safety, reliability, and performance of your bolted joints. While torque is a convenient and necessary tool, understanding its limitations is what separates amateur assembly from professional engineering.

For expert consultation on your critical bolted applications, from selecting the right high-strength fasteners to defining advanced tightening procedures, contact our technical team today.

- Beyond the Price Tag: The Real Cost of a Cheap Bolt in B2B Sourcing

- Torque vs. Preload: The Ultimate Guide to Achieving Accurate Clamp Load in Bolted Joints

- Choosing the Best Anti-Corrosion Coating for Marine Fasteners: Hot-Dip Galvanizing vs. Dacromet

- Why Are My Stainless Steel Fasteners Rusting? A Guide to Corrosion and Galling (Seizing)

- Sourcing Fasteners from China? How to Avoid the Pitfalls by Choosing a True Partner