As manufacturers of high-performance fasteners, one of the most frequent questions we hear from clients is: “I paid for stainless steel fasteners, so why am I seeing rust?” Often, this question is followed by another frustrating problem: “And why are my stainless steel bolts seizing so tightly they have to be cut off?”

You chose stainless steel for its promise of a long, corrosion-free life. So, what’s going wrong?

The truth is that stainless steel is not “rust-proof”—it is “corrosion-resistant.” And the two problems of “rusting” and “seizing” are completely different issues with different causes and solutions. With decades of manufacturing experience, we want to explain the science behind these phenomena and give you the expert knowledge to prevent them.

Part 1: The “Rusting” Problem – Understanding Stainless Steel Corrosion

The magic of stainless steel lies in an invisible, ultra-thin protective shield on its surface called a passive layer. This layer, rich in chromium oxide, forms naturally when the steel is exposed to air and protects the iron within from oxidation (rust).

However, this passive layer can be compromised.

How the Protective Layer Fails:

- Chloride Attack (The #1 Enemy): Chlorides, found in salt, are incredibly effective at breaking down the passive layer. This creates tiny, localized areas of corrosion called pitting or, if trapped in a tight space like under a washer, crevice corrosion. For clients in coastal or marine environments like Singapore, or in industries using certain chemicals, this is the primary cause of rust.

- Iron Contamination: If you use a regular carbon steel tool (like a wrench or socket) on a stainless steel screw, tiny iron particles can be left behind. These loose particles will rust on the surface, making it look like the stainless steel itself is rusting.

- Mechanical Damage: Deep scratches or gouges from improper handling can damage the passive layer, creating a weak point where corrosion can begin.

Part 2: The Solution to Rusting: Choosing the Right Grade (A2 vs. A4)

The single most important decision to prevent rust is selecting the correct grade of stainless steel for your environment.

- A2 Stainless Steel (also known as Type 304): This is the most common grade. It offers excellent corrosion resistance in general atmospheric and freshwater environments. It’s perfect for inland construction, furniture, and indoor applications.

- A4 Stainless Steel (also known as Type 316): This is the premium grade for corrosion resistance. The key difference is the addition of molybdenum, an alloy that drastically enhances its ability to resist chloride attack.

Application Guide:

| Environment | Recommended Grade | Why? |

| Indoor / General Outdoor (low pollution) | A2 (304) | Good general corrosion resistance at a lower cost. |

| Marine / Coastal / Shipbuilding | A4 (316) | Molybdenum provides superior resistance to saltwater. |

| Chemical Plants / Wastewater Treatment | A4 (316) | Resists a wider range of chemical corrosives. |

| High-Pollution Urban/Industrial Areas | A4 (316) | Withstands acid rain and industrial pollutants. |

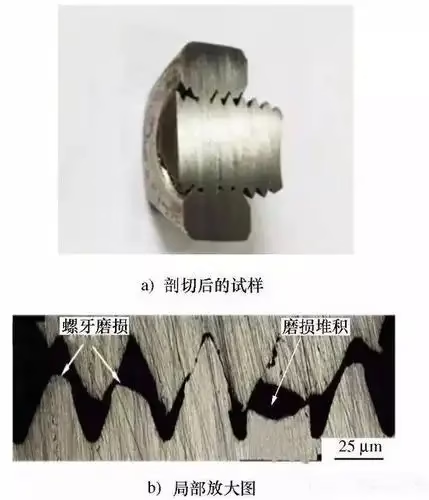

Part 3: The “Seizing” Problem – What is Thread Galling?

Now for the second issue: your bolt is stuck tight and won’t budge. This is thread galling, also known as “cold welding,” and it has nothing to do with rust.

Galling occurs when the high pressure and friction from tightening a fastener cause the protective oxide layers on the threads to rub off. The bare, clean metal surfaces of the bolt and nut threads make direct contact and essentially fuse together. Stainless steel is particularly susceptible to this because of its inherent ductility and tendency to have a “sticky” surface at a microscopic level.

Primary Causes of Galling:

- High-Speed Installation: Using power tools on high speed generates excessive heat and friction.

- Contaminants or Damaged Threads: Dirt, debris, or damaged threads increase friction dramatically.

- High-Torque Applications: The greater the pressure on the threads, the higher the risk of galling.

Part 4: The Expert Solution: How to Prevent Rust and Galling of stainless steel fasteners.

As a manufacturer, our goal is to ensure you get the performance you expect. Here are the professional solutions.

To Prevent Corrosion (Rust):

- Select the Correct Grade: This is your first and best defense. Use A4 (316) for any marine, coastal, or corrosive environments.

- Choose a Quality Manufacturer: We ensure our fasteners go through a passivation process after manufacturing. This chemical treatment removes any surface contamination and helps build a thicker, more robust passive layer.

To Prevent Galling (Seizing):

- Use a Lubricant: This is the #1 most effective solution. Apply a high-quality anti-seize compound to the threads of the bolt before installation. This creates a barrier between the metal surfaces.

- Slow Down Installation: Avoid high-speed impact wrenches. Tighten nuts slowly and deliberately. This reduces heat and allows the pressure to be applied more evenly.

- Ensure Cleanliness: Always use clean, undamaged fasteners. A quick inspection before installation can save hours of frustration later.

(Internal Link Recommendation):

- Link from “passivation process” to a technical blog post or a page on your site explaining “Our Manufacturing Process” to showcase your expertise.

Conclusion: Knowledge is Your Best Tool

Understanding that “rusting” and “seizing” are separate issues is the key to solving them. Prevention comes down to two simple principles: choosing the right material for the environment and using the right installation technique.

When you partner with a knowledgeable manufacturer, you don’t just buy a product; you gain access to the expertise that ensures your project’s success and longevity.

Why Choose Boltech Fasteners Stainless Steel Fasteners?

- Expert Guidance: Our engineers will help you select the perfect grade (A2, A4, or special alloys) for your specific application.

- Controlled Manufacturing: We guarantee a proper passivation process for maximum corrosion resistance.

- Full Traceability: We provide genuine Material Test Certificates (MTCs) to verify the chemical composition and quality of our steel.

- Proven Experience: We have decades of experience supplying high-performance fasteners for the most demanding marine and industrial projects in Southeast Asia and across the globe.

- Beyond the Price Tag: The Real Cost of a Cheap Bolt in B2B Sourcing

- Torque vs. Preload: The Ultimate Guide to Achieving Accurate Clamp Load in Bolted Joints

- Choosing the Best Anti-Corrosion Coating for Marine Fasteners: Hot-Dip Galvanizing vs. Dacromet

- Why Are My Stainless Steel Fasteners Rusting? A Guide to Corrosion and Galling (Seizing)

- Sourcing Fasteners from China? How to Avoid the Pitfalls by Choosing a True Partner