As someone who has worked on countless projects, from assembling furniture to building outdoor decks, I’ve seen one question cause more confusion than almost any other: Do you need to drill a pilot hole for a self-tapping screws? The name “self-tapping” is a bit misleading, and relying on it can be the difference between a secure joint and a split piece of wood.

The most reliable answer is: Yes, in most cases, drilling a pilot hole is a professional best practice that you shouldn’t skip.

This guide is built on years of hands-on experience and industry best practices. We’ll cover when to drill, what size hole you need, and how to ensure your project is a success.

Image Description: A self-tapping screw being driven into a pre-drilled pilot hole in wood, demonstrating best practice.

1. Experience Shows: The Material is Key

The first thing a seasoned pro considers is the material. A self-tapping screw works by cutting its own threads, but forcing it into a dense material without a pilot hole is asking for trouble.

- Softwood (e.g., Pine, Cedar): While you can sometimes drive a small screw directly, I’ve seen wood split one too many times, especially near an edge. A pilot hole is cheap insurance against ruining your workpiece.

- Hardwood (e.g., Oak, Maple): A pilot hole is non-negotiable. From personal experience, trying to force a screw into oak without a pilot hole will either snap the screw head, strip it, or split the wood every single time.

- Plastic: Drilling a pilot hole is crucial. It prevents unsightly and weakening cracks from forming around the screw.

- Thin Sheet Metal (up to ~22 gauge / 0.75mm): This is where self-tapping screws shine. However, for a cleaner entry, a specialized “self-drilling” screw with a drill-bit tip is an even better choice.

- Thicker Metal (1mm and up): A pilot hole is mandatory. A standard self-tapping screw is not designed to displace thick metal. You will burn out your drill’s motor or break the screw.

2. The Expert’s Choice: Why Drilling a Pilot Hole is Best

Beyond just preventing disasters, drilling a pilot hole offers significant advantages that lead to a truly professional result.

- Prevents Material Damage: This is the #1 reason. It’s the best way to prevent wood splitting, a common issue discussed in-depth by woodworking experts.

- Creates a Stronger Joint: A pilot hole allows the screw threads to form clean, deep channels, maximizing their engagement with the material. This drastically increases the screw’s pull-out strength.

- Reduces Driver and Screw Stress: It takes far less torque to drive a screw into a pilot hole. This means no more stripped screw heads or broken screws, and less strain on your drill and your wrist.

- Guarantees Precision: A pilot hole acts as a perfect guide, ensuring the screw goes in straight and exactly where you intended.

3. The Authoritative Guide: Pilot Hole & Screw Size Chart

The most critical step is matching the drill bit to the screw. The principle is to drill a hole that accommodates the screw’s solid core (minor diameter) while allowing the threads (major diameter) to bite firmly into the surrounding material.

This chart is based on industry standards for creating strong, reliable joints.

| Screw Size (Gauge) | Major Diameter (Approx.) | Pilot Hole in Softwood | Pilot Hole in Hardwood & Plastic | Pilot Hole in Metal |

| #4 | 2.9mm (7/64″) | 1.6mm (1/16″) | 2.0mm (5/64″) | 2.4mm (3/32″) |

| #6 | 3.5mm (9/64″) | 2.0mm (5/64″) | 2.8mm (7/64″) | 3.2mm (1/8″) |

| #8 | 4.2mm (5/32″) | 2.8mm (7/64″) | 3.2mm (1/8″) | 3.5mm (9/64″) |

| #10 | 4.8mm (3/16″) | 3.2mm (1/8″) | 3.5mm (9/64″) | 4.0mm (5/32″) |

| #12 | 5.5mm (7/32″) | 3.5mm (9/64″) | 4.0mm (5/32″) | 4.8mm (3/16″) |

| #14 | 6.3mm (1/4″) | 4.0mm (5/32″) | 4.8mm (3/16″) | 5.5mm (7/32″) |

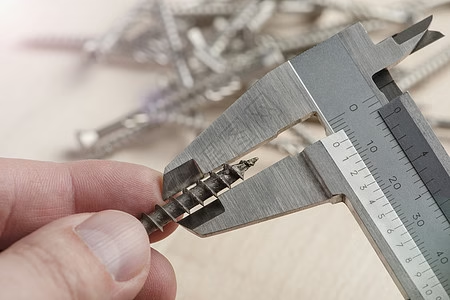

4. How to Accurately Measure Your Screw

For maximum precision, especially with an unknown screw, use a digital or dial caliper. It’s a foundational tool for accurate work.

- Measure the Major Diameter: Gently close the caliper jaws on the outermost edges of the screw’s threads. This is the screw’s nominal size.

- Measure the Minor Diameter: Carefully measure the solid core of the screw between the threads.

- Select Your Drill Bit: Your pilot hole drill bit should be equal to or just slightly larger than the minor diameter. This is the most accurate method used by machinists and engineers. For a great visual guide, you can learn how to properly use digital calipers from this helpful article by The Family Handyman.

5. The Exception: When Can You Skip the Pilot Hole?

While not best practice, there are specific, low-risk scenarios where you might skip it:

- Non-Structural, Temporary Fixes: If the hold is just temporary and not supporting any significant weight.

- Using True Self-Drilling Screws: Do not confuse “self-tapping” with “self-drilling.” Self-drilling screws, often known by the brand name Tek Screws, have a specialized drill bit forged into their tip. These are explicitly designed to drill their own holes in light-to-medium gauge metal.